News

PACKING & SERVICE

Managing quality of products is an extremely important condition, deciding the survival of any business.

In addition to the mission to bring customers traditional products, new products that the market has not exploited, SAO THANH very interested and focused on the strict management of product quality before delivery to customers.

- As soon as the raw materials have been extracted from the mine, the Quality Control team (QC) of the factory has to classify the raw materials for inclusion in the raw material warehouse, including high quality products used to process the valuable products as Gothic, Honed …and less expensive materials to make low cost products such as Tumbled ..

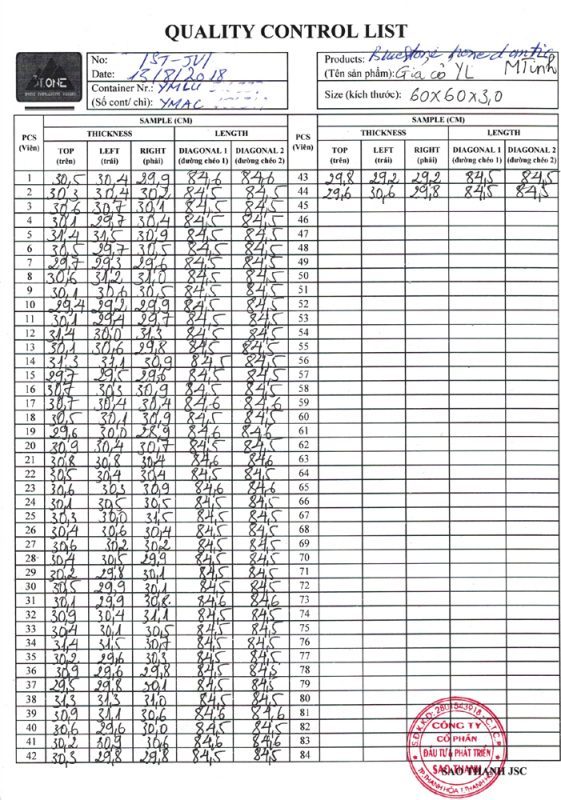

- After processing, the goods are assembled at the right place for packing into wooden crates … the QC will check with the measuring equipment to ensure the product quality and size according to the content right and false permission … each stone we checked from the color, size before closing in the wooden crates … each QC will be given a similar number to take responsibility before the product that I have chosen …

- For some high-end products, in addition to the documents in the export records such as Bill of lading, Invoice … we always have a CE certificate in which all data of each sample is recorded. Randomly selected, including measurements of length, width, diagonal, diagonal, etc. In each box will place randomly selected tablets with equivalent data and be confirmed by the employee. QC who is responsible for the product of his choice.

SAO THANH TEAM.

Tiếng Việt

Tiếng Việt